Rigid and Flex Circuits

Rigid and Flex Circuits

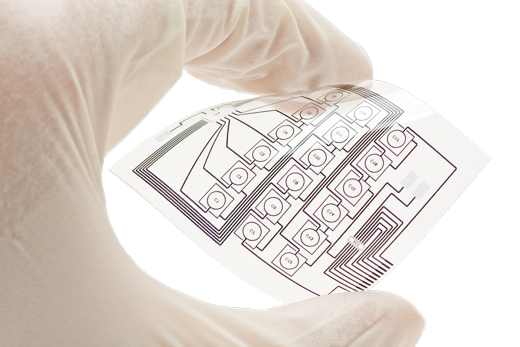

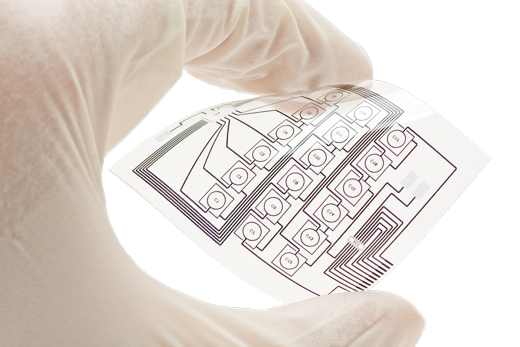

What Are Flexible Printed Circuits?

Flexible printed circuit (FPC) designs share many advantages over printed circuit boards (PCB), however, share many of the same challenges PCB designs. They are also excellent alternatives to membrane switches where ruggedness, reliability, and/or component use are necessary objectives. The very nature of a flex circuit being able to bend and flex make it as much a mechanical device as an electrical one. This creates a special set of requirements unique to flexible circuitry. Understanding how these requirements interact is key to a successful, and cost effective solution.

Flexible printed circuits are designed to three (3) Circuit Classes:

- Class 1 – These circuits have the minimum inspection, testing, and performance requirements, as defined by IPC-6013. These circuits are typically designed for disposable electronics.

- Class 2 – These circuits have moderate inspection, testing, and performance requirements, and are generally designed for use in many consumer electronics.

- Class 3 – These circuits have the highest levels of inspection, testing, and performance requirements. As such, these circuits are generally designed for medical devices, and many military and defense applications.

In addition to classes, flexible printed circuits are offered in four (4) type variations:

- IPC 6013 Type 1 – Single layer, with insulating material on one or both sides, and access to the conductors.

- IPC 6013 Type 2 – Two layers with insulating film between both layers; plated interconnect holes; and access to the conductors are one or both sides.

- IPC 6013 Type 3 – Three or more layers with insulating film between both layers; plated interconnect holes; and access to the conductors are one or both sides.

- IPC 6013 Type 4 – Two or more layers with insulating film between both layers; ability to incorporate a rigid PCB; plated interconnect holes; and access to the conductors are one or both sides.

Backlighting Your Flexible Printed Circuit

If you would like to backlight your application, the flexible printed circuit (FPC) construction would incorporate either light guides or LEDs for uniform lighting. Other options for backlighting are fiber optic backlighting and EL backlighting. Depending on the requirements of your application such as thickness preference, shape, environmental exposure, and other unique specifications, the backlighting options would vary and be selected specifically to fit the function of your device. Using the latest LED powered lighting can reduce cost and reduce power used by a device. Since many devices today are portable, this backlighting solution is more relevant than ever.

A variety of applications that use backlighting solutions are: remote controls, laboratory equipment, airplane dashboards, medical devices in dimly lit operating rooms, consumer appliances, such as coffee makers and microwaves, laptop keyboards, and many other applications that we all come in contact with daily or sporadically.

We have various backlighting samples that you can evaluate and consider for your application. Please feel free to submit a sample request and we’ll send you a variety of useful samples and tools you can experiment with for your application