Custom Assemblies

Custom Assemblies

What Are Assemblies?

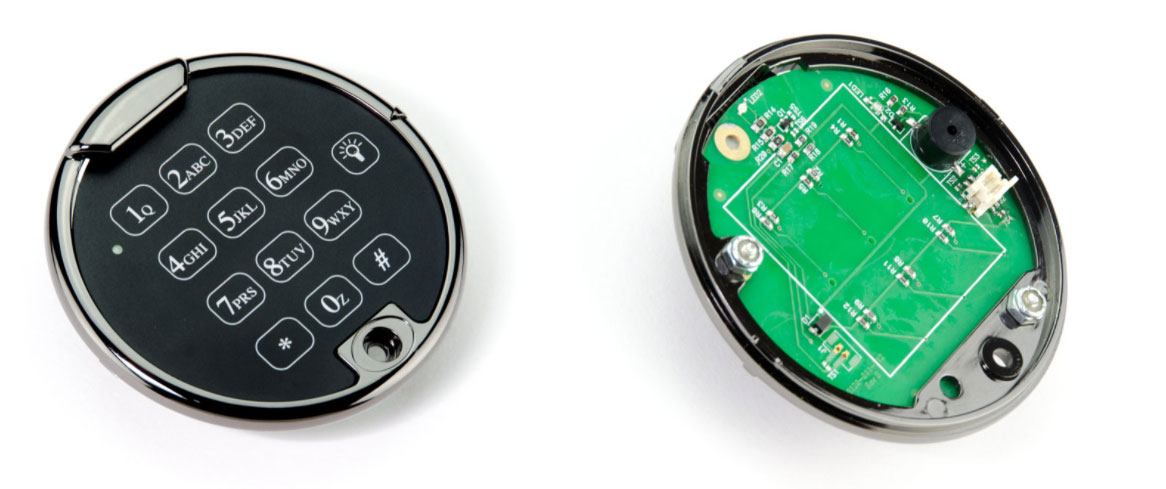

Behind every successful project is a smart and talented team of engineers. Thanks to many years of experience in the interface industry, Nelson Miller is able provide you with a complete one-stop-shop solution for modules and value-added assemblies for all product types including custom plastic injection molding, in-mold decorating, switches, and keypads.

Features of Nelson Miller Assemblies

Leveraging our expertise and benefits in custom plastic injection molding, in-mold decorating, switches, and keypads, we can provide a fully optimized and tested application that reduces supply chain complexity and your total product costs.

For in-house mold, tool design and fabrication you’ve come to the right place. All our factories are ISO, (2015 and AS9100D) certified. We also have our ITAR certificate and our Berlin facility is NADCAP approved for anodizing.

Benefits of Assembly

- Full design support and service from local technical teams in your region

- Wide range of keypad and membrane switch cosmetics, including attractive finishes, decorative textures and metallic color effects

- In-house dome array manufacturing and extensive tactile feeling knowledge

- One-stop-shop solutions provider, one point of contact

- Using sophisticated simulation software, we custom-engineer light guide films that provide your product with a uniform backlighting solution per your specifications.

- Circuits: Flexible (FPC), or rigid printed circuit board (PCB) design capabilities.

- Final product assembly in clean environments in all of our facilities

- Final 100% functional testing available