The company will serve as NMG’s in-country authority for custom thermoplastic injection molding and related services.

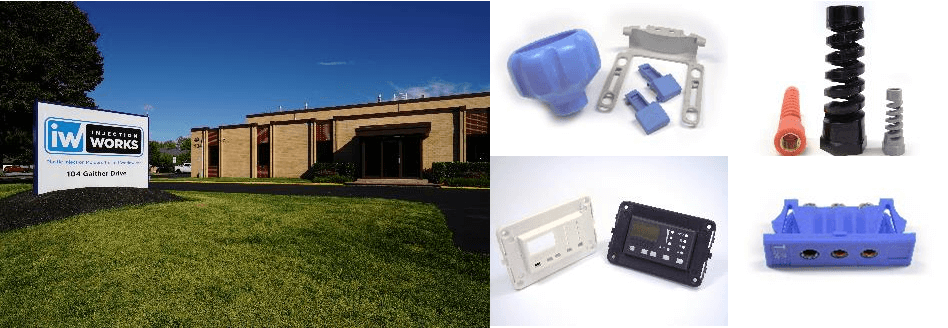

Nelson Miller Group is pleased to announce our investment in Mount Laurel, NJ, manufacturer Injection Works, Inc. Formed by the consolidation of Eptech and A.L.Hyde in 1997, Injection Works has provided custom thermoplastic injection molding and associated services for over 35 years, with plastics expertise dating back to the 1950s.

With the addition of Injection Works, NMG greatly increases our plastic injection molding capabilities within the United States. The knowledgeable Injection Works team, which consists of approximately 35 people, brings with it valuable subject matter expertise. The addition of its 46,000-square-foot facility in New Jersey enables quality, 24-hour thermoplastic manufacturing leveraging advanced equipment for injection molding and value-added secondary services, such as in-mold decorating, overmolding, hot stamping, and pad printing, among others. The company also provides in-house 3D prototype printing, customer tooling management, assembly, and packaging.

“We’re thrilled to welcome Injection Works to our organization,” said Jim Kaldem, President and CEO of Nelson Miller Group. “We look forward to growing our presence in New Jersey and investing in new training and technologies that strengthen our position as a premier partner to companies looking to produce high-quality, cost-effective plastic parts.”

Adds Chris Rapacki, Co-Founder CEO of Injection Works, “Nelson Miller Group shares in our commitment to trust, dependability, quality, and cost-effective solutions. By joining NMG, Injection Works opens the door to new technologies, manufacturing solutions, and supply chain support for our customers. We’re excited for this opportunity to share our top-notch, American-based injection molding capabilities with a broader audience, while continuing to serve our existing customers with our longstanding commitments to quality and cost.”

About Injection Works

Injection Works provides custom thermoplastic injection molding and related services to a variety of clients in Construction, Electrical, Furnishings, Industrial, Medical, and Transportation market segments, and we believe that our consistent investments in team training, communications technology and the most advanced production assets available differentiate us and support our single purpose – To provide our customers with confidence, security and enhanced competitive advantages in their marketplace. We look forward to partnering with new strategic clients as we continue to support our tremendously loyal existing customer. Follow Injection Works on LinkedIn.